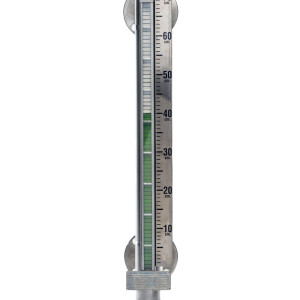

Magna-Site™ Magnetic Level Gauge

The KENCO Magna-Site is a magnetic level gauge used to determine the volume of liquid contained within a tank. Because the Magna-Site eliminates the need for glass, high pressure applications and hazardous locations are protected from the danger of a chemical spill due to glass failure.

The KENCO Magna-Site utilizes three major components: the gauge housing chamber, the magnetic float, and the magnetic flag assembly (Indicator).

The gauge housing chamber is typically mounted adjacent to the side of the tank. It is constructed to withstand the same temperatures and pressures as the tank itself. It is equipped with the appropriate tank mounting connections for easy installation and to allow equalization of liquid level in tank and gauge.

Inside the gauge housing chamber is the magnetic float, which contains radially-positioned magnets to provide a 360 degree magnetic flux field. Each float is internally weighted based on specific gravity so that the liquid level in the gauge coincides with the location of the magnets inside the float.

Attached to the gauge housing chamber is the magnetic flag assembly. This is the visual means of liquid level indication for the KENCO Magna-Site. The assembly is made up of a series of bicolored, fluorescent flags. As the magnetic float rises and falls with the liquid level in the gauge housing chamber, a magnet embedded in each flag reacts to the 360 degree magnetic flux of the float. This magnetic interaction causes each flag to rotate 180 degrees. The flags below the magnetic flux of the float will flip to fluorescent green, while those flags above the float level remain bright white. Other colors are available upon request (red/white, black/yellow, blue/white).

When your application priorities are safety, visibility, and accuracy, the KENCO Magna-Site is the low-maintenance, cost-effective solution.

KTC Magnetostrictive Transmitter

The KTC chamber mounted liquid level transmitter is a continuous multi-functional magnetostrictive transmitter that provides product level to the user via Analog (4-20mA) with HART®, Modbus RTU (Remote Terminal Unit) or DDA (Direct Digital Access). Magnetostrictive technology is one of the most accurate and repeatable level technologies available to date.

Principle of Magnetostriction

The principles of magnetostriction are used to create a reliable position measurement system for use in industrial environments. Inside the sensor, a torsional strain pulse is induced in a specially designed magnetostrictive waveguide by the momentary interaction of two magnetic fields. One field comes from a magnet located inside a float which moves up and down inside the KMLG magnetic level gauge chamber. The other field is generated from a current pulse which is applied to the waveguide. The interaction between these two magnetic fields produces a strain pulse which travels at sonic speed along the sensor waveguide until the pulse is detected at the head of the transducer. The position of the moving float magnet is precisely determined by measuring the elapsed time between the application of the current pulse and the arrival of the strain pulse. As a result, a reliable position measurement system is created that is capable of providing an accurate and repeatable measurement.

Features

- Maximum safety – No glass is used in the construction.

- Optimum visibility – Fluorescent flags are visible from great distances

- Float with 360° magnetic flux – Maintains a strong magnetic field in all directions; turbulent liquids will not cause flag assembly to give an inaccurate level indication

- Double flag protection – Flags are hermetically sealed inside a PTFE encapsulated assembly which is shrouded by a 300 series stainless steel enclosure on three sides with a UV stabilized high-impact clear polycarbonate shield

- Adjustable viewing angles – Flag assembly can be rotated to any angle to provide maximum visibility

- Multiple mounting options – Engineered construction allows for a variety of mounting configurations

- Compatibility – A broad range of materials can be used to withstand harsh chemicals

- Remote level indication – Explosion-proof magnetostrictive level sensor/transmitter provides an output signal via Analog (4-20mA) with HART®, Modbus RTU (Remote Terminal Unit) or DDA (Direct Digital Access)

- Height scale – 304 stainless steel with no. 3 finish and large etched characters/lines for easy reading

- High/Low level switches – Explosion proof switches can signal an alarm, operate a pump/valve or act as an emergency shut down

- Convenience – Easy installation and very low maintenance

- Warranty – Two year guarantee against defects

- Reliability – KENCO has been building magnetic liquid level indicators since 1985

- Compliance with the requirements of ASME code for pressure piping, process piping, B31.3

- Certificate of Authorization including CRN numbers issued by Alberta Boilers Safety Assn. for use in Canadian provinces and territories

Industries Served

- Chemical and Petrochemical Refineries

- Water and Waste Treatment

- Pulp and Paper Processing

- Power Plants

- Pharmaceutical Processing

- Food and Beverage Processing

Common Applications

- Fuels and Solvents

- Oil Production and Refining

- Lubrication Oils

- Detergents and Soaps

- Boiler Feedwater Tanks

- Fertilizers and Pesticides

- Ammonia Tanks

- Scrubber Tanks

- Storage Tanks

- Acid Tanks

Gallery

Specifications

Float Characteristics

- 360° magnetic-flux field provides constant interaction with flag assembly in turbulent liquids

- Internally weighted based on specific gravity so that location of magnets inside float coincide with liquid level in gauge

- Cylindrical geometric shape ensures more accuracy in interface specific gravity applications

- Rare earth magnet assembly has an unusually high energy output volume and is highly resistant to demagnetization; they will not demagnetize at high temperatures like ceramic magnets

- Standard float material is 316 stainless steel. Other float materials available, including: Titanium, Hastelloy™, Inconel™, Alloy 20, Aluminum, PVC and CPVC

- Standard float good to a minimum specific gravity of 0.50. Custom floats for lower specific gravities available.

- 360° magnetic-flux field is ideal for interaction with KENCO magnetostrictive transmitter

- Float is non-vented, so vapors can not condense inside float

- Compact length minimizes ground clearance requirements

Flag Assembly

- Fluorescent flags for maximum visibility

- No glass in flag assembly

- Shield is UV stabilized high-impact clear polycarbonate

- Chamber is hermetically sealed and nitrogen filled to prevent internal condensation and ensure 100% flag rotation every time

- Totally enclosed with clear FEP Teflon™ tubing for maximum chemical resistance

- 300 series stainless steel enclosure provides maximum protection from puncture of FEP Teflon™ tubing

- 300 series stainless steel is more compatible to corrosive environments than aluminum

- Double O-ring seal assures that the flag assembly will not lose its nitrogen-filled atmosphere

- Each flag contains an Alnico 8 magnet, making each flag highly resistant to demagnetization

- Flags are UV stabilized, high-temperature thermoplastic and molded in color to prevent fading

- No ceramic magnets are used

- Maximum constant temperature of 400°F (204.4°C)

- About the sealing process: The end block on one end of the flag rail is equipped with a positive stop charge valve to allow the flag assembly to be hermetically sealed. The flag assembly is attached to a vacuum pump through a manifold which is connected to a cylinder of ultra high-purity nitrogen gas. We evacuate the flag assembly with a vacuum pump and then internally pressurize it with ultra high-purity nitrogen gas.

High-Temperature Flag Assembly Features

- Maximum constant temperature of 800°F (426.6°C)

- Flags are 316 stainless steel

- Flag color is heat cured at 400°F (204.4°C) with heat resistant paint

- All 300 series stainless steel flag assemblies are ideal for severe environment

- Alnico 8 magnets are nickel plated to withstand severe environments

Transmitter Features

Level Output

- Measured Variable = Product Level

- Full-Range = 0.5 to 25 ft. (152 mm to 7.6 m)

- Non-linearity Full span = 0.020% F.S. (Independent BSL) or 1/32″ (0.794mm), whichever is greater.

- Repeatability = 0.001 % F.S. or 0.015″. (0.381 mm), whichever is greater.

- Inherent Accuracy = ±0.039 (±1mm)

- Sensor Operating Temperature = Operating temperature is -40°F to 300°F (-40°C to 149°C ). Contact Kenco for higher temperature requirements.

Electronics

- Input Voltage Range = 10.5 to 28 Vdc

- Fail Safe =

Analog (4-20mA) with HART: Low 3.5 mA default or High 22.8 mA

Modbus RTU / DDA: High, Full Scale - Reverse Polarity Protection = Series diode

- Safety Approval =

– FM Intrinsically Safe Class I, Division 1, Groups A, B, C, D and Class I, Zone 0/1, AEx ia IIC.

– FM Explosion Proof Class I, Division 1, Groups A, B, C, D and Class I, Zone 0/1, AEx db IIB+H2.

– FMC Intrinsically Safe Class I, Division 1, Groups A, B, C, D and Class I, Zone 0/1, Ex ia IIC.

– FMC Explosion Proof Class I, Division 1, Groups B, C, D and Class I, Zone 0/1, Ex db IIB+H2.

– Consult factory for ATEX, IECEx, INMETRO options

Calibration

- Zero Adjust Range = Anywhere within the active length

- Span Adjust Range = FS > 0.5 ft. (152 mm) from zero

Environmental

- Enclosure Rating = IP65

- Sealing = Potted sensor cartridge

- Humidity = 0 to 100% relative humidity

- Operating Temperature =

Electronics: -40 to 160°F (-40 to 71°C)

Sensing Element: -40 to 300°F (-40 to 149°C) - Materials =

Sensor housing: 316L stainless steel; contact factory for other materials

Electrical Housing: Epoxy coated aluminum or 316 S.S.

Field Installation

- Transmitter Order Length = Up to 25 ft (7.6 meters)

- Wiring = Two-wire connection, shielded cable or twisted pair to screw terminals through a 3/4 in. (12.7 mm) NPT conduit opening or M20 opening for ATEX/IEC version

Display

- Measured Variables = Liquid Level

- Update Rate = 0.3 seconds

- Size = 0.5″

- Measurement = % of span, a 4-20mA output or any unit of measure

- Digital Display for zero and span setting and readout

- Immune from electrical and mechanical noise

- HART® Communications standard

- No maintenance required

Explosion-Proof High-or-Low Level Switches

- Can activate alarms, pumps or valves when the liquid reaches high or low levels

- Does not come in contact with process liquid

Model 9958: Latching Switch

- C-UL-US approved for Class I, Div. 1, Div. 2, Groups C & D, Class II, Div. 1, Div. 2, Groups E, F, & G

- Housing Material: Aluminum (Other Materials Available)

- Switch: SPDT, latching reed normally open or normally closed form C contacts

- Maximum temperature: 221°F (105°C). Consult factory for higher temperatures.

- Maximum switching volts: 100VDC, 140 VAC

- Maximum switch current: 0.20 Amps DC, 0.14 Amps AC

- Maximum power: 4 watts

- Conduit Connection: 1/2″ female NPT

Model 9959: Non-Latching Switch

- C-UL-US approved for Class I, Div. 1, Div. 2, Groups C & D, Class II, Div. 1, Div. 2, Groups E, F, & G

- Housing Material: Aluminum (Other Materials Available)

- Switch: SPST, non-latching reed normally open form A contacts

- Maximum temperature: 221°F (105°C). Consult factory for higher temperatures.

- Maximum switching volts: 100VDC, 140 VAC

- Maximum switch current: 0.25 Amps DC, 0.18 Amps AC

- Maximum power: 7 watts

- Conduit Connection: 1/2″ female NPT

Height Scales

- Standard scales are 304 stainless steel with no.3 finish

- Standard scales show height in feet/inches or meters/centimeters

- Large numerical characters offer increased visibility

- Standard scale division marks/characters are etched and paint filled

- Can be calibrated for any unit of measure

- Laser etched 316 stainless steel available upon request

Insulation Blankets

- Withstands temperatures up to 750°F (398.8°C )

- Standard shell material is silicone impregnated fiberglass cloth

- Also available in other materials based on application

- Steam tracing also available

Installation Instructions

-

KTC Transmitter Manual (2019-Present) -

KMD Transmitter Manual (2001-2019) -

Magna-Site Magnetic Level Gauge Manual -

Magna-Site Magnetic Level Gauge (MLG-D) Manual -

9958 - 360 Degree and Bar Magnet Manual -

9959 - 360 Degree and Bar Magnet Manual -

KTC Transmitter Interface Manual (HART) -

KTC Transmitter Interface Manual DDA -

KTC Transmitter Interface Manual (MODBUS)

Related Documents

-

Magna-Site Magnetic Level Gauge Literature -

Application Worksheet MLG-D (Flanged) -

Application Worksheet MLG-D (Threaded) -

Magna-Site Magnetic Level Gauge Application Worksheet -

9958-9959 SWITCH UL CERTIFICATE -

KTC TRANSMITTER - (CANADA) EXPLOSION PROOF ANALOG OUTPUT WIRING SCHEMATIC -

KTC TRANSMITTER - (U.S.) EXPLOSION PROOF ANALOG OUTPUT WIRING SCHEMATIC -

KTC TRANSMITTER - (CANADA) EXPLOSION PROOF DIGITAL OUTPUT WIRING SCHEMATIC -

KTC TRANSMITTER - (U.S.) EXPLOSION PROOF DIGITAL OUTPUT WIRING SCHEMATIC -

KTC TRANSMITTER - (CANADA) INTRINSICALLY SAFE ANALOG OUTPUT WIRING SCHEMATIC -

KTC TRANSMITTER - (U.S.) INTRINSICALLY SAFE ANALOG OUTPUT WIRING SCHEMATIC -

KTC TRANSMITTER - (CANADA) INTRINSICALLY SAFE DIGITAL OUTPUT WIRING SCHEMATIC -

KTC TRANSMITTER - (U.S.) INTRINSICALLY SAFE DIGITAL OUTPUT WIRING SCHEMATIC -

KTC CEC Intrinsically Safe Certificate -

KTC NEC CEC Intrinsically Safe Certificate -

KTC CEC Explosion Proof Certificate -

KTC NEC Explosion Proof Certificate