Chemical Injectors

U.S. Patent # 7,137,569

Application

KENCO Chemical Injectors are designed to inject and properly atomize corrosive chemicals into the turbulent stream of a process system pipeline. The KENCO Chemical Injector will minimize the possibility of corrosive chemical build-up on the walls of the pipeline. KENCO Chemical Injectors are recommended for use in pipelines with a flow-rate velocity of 40 feet per second (12.192 meters per second), or less.

Industries Served

- Natural Gas Transmission and Distribution

- Oil and Gas Production and Refining

- Petrochemical Processing

- Water Treatment

- Fluid Processing

- Pulp and Paper Processing

KINJ & KINJM Injector Features

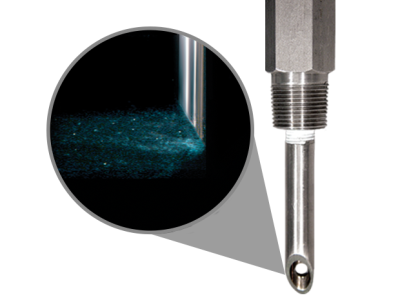

- Patented aspirator tip design on injector disperses chemical evenly into process

stream and away from pipe walls - Check valve in injector eliminates backflow

- Injector is ideal for high pressure applications up to 6000 psig (413.68 bar)

- Injector has been designed so that it can be mounted in any orientation

- Standard insertion lengths available from 1-1/2” to 24” long. Custom sizes

also available. - Injector available in 316 Stainless Steel, Hastelloy C-276, and CPVC

- Ball-check material in 316 Stainless Steel injectors is 316 Stainless Steel and ballcheck material in CPVC and Hastelloy injectors is ceramic.

- Ball-check retainer material in 316 Stainless Steel and CPVC injectors is Inconel.

Ball-check retainer material in Hastelloy injectors is Hastelloy. - Standard Injector chemical feed port is 1/2” NPT and process connection is

1/2” or 3/4” NPT. Flanged process connections also available, consult factory

for options.

KRINJ Injector Features

- Patented aspirator tip design on injector disperses chemical evenly into

process stream and away from pipe walls - Ball valve assembly isolates pipeline from injector assembly when injection is

not required - Compression seal holds the assembly from back pressure

- Safety line prevents the injector assembly from being completely withdrawn

and protects against blowout - Standard ball valve assemblies available in 316 Stainless Steel, Alloy 20, CPVC

and Brass. Standard Injector Nozzle assemblies available in 316 Stainless Steel,

Hastelloy C-276 and CPVC. - Ball-check material in 316 Stainless Steel injectors is 316 Stainless Steel and

ball-check material in CPVC and Hastelloy injectors is ceramic. - Ball-check retainer material in 316 Stainless Steel and CPVC injectors is Inconel.

Ball-check retainer material in Hastelloy injectors is Hastelloy. Optional check

valve and/or body bleed valve available. - Standard Retractable Injector chemical feed port is 1/2” NPT. Process

connection is 3/4” NPT. Flanged process connections also available, consult

factory for options.

Gallery

Specifications

Temperature & Pressure Ratings

MODEL KRINJ Temperature & Pressure Ratings

| Valve Material | Maximum Working Pressure | Maximum Operating Temperature |

| Brass | 150 psig (10.34 bar) | up to 350°F (176.6°C) |

| 316 SS | 150 psig (10.34 bar) | up to 400°F (204.4°C) |

| Alloy 20 | 150 psig (10.34 bar) | up to 400°F (204.4C) |

| CPVC | 150 psig @ 73°F (10.34 bar @ 23.8°C ) 100 psig @ 150°F (6.89 bar @ 65.5°C ) |

up to 200°F (93.3°C) |

MODELS KINJ & KINJM Temperature & Pressure Ratings

| Injector Material | Maximum Working Pressure |

Maximum Operating Temperature |

| 316 SS | 6000 psig (413.68 bar) | 800°F (426.6°C) |

| HC-276 | 6000 psig (413.68 bar) | 800°F (426.6°C) |

| CPVC | 340 psig @ 73°F (23.44 bar @ 22.7°C) 150 psig @ 150°F (10.34 bar @ 65.5°C) |

200°F (93.3°C) |

Injector Style

- KINJ = Standard Injector

- KINJM = Mini Injector

- KRINJ = Retractable Injector

Process Connections

KINJ:

- 50 = 1/2″ MNPT

- 75 = 3/4″ MNPT

KINJM:

- 125 = 1/8″ MNPT

- 250 = 1/4″ MNPT

KRINJ:

- 75 = 3/4″ MNPT

Materials of Construction (Injector)

KINJ:

- S6 = 316 Stainless Steel (Standard)

- HC = Hastelloy C 276 w/Ceramic Ball

- CP = CPVC w/Ceramic Ball

KINJM:

- S6 = 316 Stainless Steel (Standard)

- HC = Hastelloy C 276 w/Ceramic Ball

KRINJ:

- CP = CPVC

- S6 = 316 Stainless Steel

- HC = Hastelloy C 276

Insertion Length (Injector)

KINJ:

- L3 = 3″ for 4″ to 6″ O.D. Pipe Lines

- L5 = 5″ for 8″, 10″ and 12″ O.D. Pipelines

- L(_) = Custom Lengths Up To 24″

KINJM:

- L(_) = Custom Lengths up to 6″

KRINJ:

- L(_) = Custom Length Up To 24″

Material of Construction (Valve-KRINJ)

- B = Brass

- S6 = 316 Stainless Steel

- A20 = Alloy 20

- CP = CPVC

Compression Seal Material (KRINJ)

- B = Buna-N

- V = Fluorocarbon

- A = Aflas

- E = Ethylene Propylene

- K = Kalrez

Installation Instructions

Related Documents

Technical Drawings

-

KINJ-50-CP-LXX -

KINJ-50-HC-LXX -

KINJ-50-S6-LXX -

KINJ-75-CP-LXX -

KINJ-75-HC-LXX -

KINJ-75-S6-LXX -

KINJM-125-S6-LXX -

KINJM-25-S6-LXX -

KRINJ-75-CP-10.75-B-CVB -

KRINJ-75-CP-10.75-B-CVN -

KRINJ-75-CP-10.75-B-CVN -

KRINJ-75-CP-8.5-CP-CVB -

KRINJ-75-CP-8.5-CP-CVN -

KRINJ-75-HC-10.75-B-CVB -

KRINJ-75-HC-10.75-B-CVN -

KRINJ-75-HC-9-A20-CVB -

KRINJ-75-HC-9-A20-CVN -

KRINJ-75-S6-10.75-B-CVB -

KRINJ-75-S6-10.75-B-CVN -

KRINJ-75-S6-9-S6-CVB -

KRINJ-75-S6-9-S6-CVN