Ultrasonic Liquid Level Switches

Ultrasonic liquid level switches are used in a wide variety of applications to detect the location of level in a process or storage vessel. These switches can be used in virtually any liquid. A complete offering of materials and mounting configurations are available to meet your application needs.

Principle of Operation

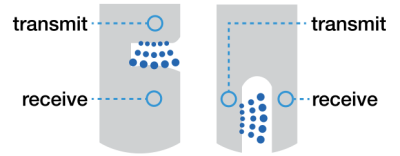

Ultrasonic switches use piezoelectric crystals to transform electrical energy into mechanical motion (sound). The Transmit Crystal sends a pulse of sound through the space between the crystals, to the Receive Crystal. If the space is filled with air, gas or vacuum, the Receive Crystal does not detect the sound pulse. However, if the space is filled with liquid, any liquid, the pulse is detected by the receive crystal, and the switch output changes.

The Model KUST and KUSG are designed for industrial applications. The Model KUSG contains a remote-test feature that allows you to test the operation of the switch and sensor on-demand. The Model KUSO is a low-cost alternative for OEMs (Original Equipment Manufacturers).

Product Features

- Not reliant on chemical properties of the liquid

- No moving parts

- Simple installation with no calibration necessary

- Available in a wide variety of process connection materials

- Remote self-test to verify operation of the electronics and sensor (Models KUST & KUSG)

- Vibration Resistant

Industries Served

- Chemical

- Petroleum

- Water & Wastewater

- Pharmaceutical

- Pulp & Paper

- Power

- Aerospace

Common Applications

- Oils and other hydrocarbons

- Solvents

- Water

- Acids

- Caustics

- Condensate

- Clean Liquids

Gallery

Specifications

Model KUST

Input Power Options

- 90-240VAC

- 9-30VDC (Loop Power)

- 24VDC

Output Options

- Relay = 10A DPDT

- Loop Power = 4-20mA

Temperature Range

- Electronics = -20°F to 158°F (-28.8°C to 70°C)

- Sensor = -4°F to 302°F (-20°C to 150°C)

Pressure Range

- 316L S.S. = Vacuum to 1000 psig (68.94 bar)

- CPVC = Vacuum to 150 psig (10.34 bar)

Sensitivity (Signal-to-Noise Ratio):

- 500:1

Repeatability

- ±0.079″ (±2mm)

Response Time

- 0.5 Seconds Fixed (Delay Available)

Model KUSG

Input Power Options

- 90-240VAC

- 9-30VDC (Loop Power)

- 24VDC

Output

- Relay = 10A DPDT

- Loop Power = 4-20mA

Temperature Range

- Electronics = -20°F to 158°F (-28.8°C to 70°C)

- Sensor (Metal)= -4°F to 350°F (-20°C to 176.6°C)

Pressure Range

- 316L S.S./Monel/Titanium = Vacuum to 1000 psig (68.94 bar)

- CPVC/Kynar = Vacuum to 150 psig (10.34 bar)

Sensitivity (Signal-to-Noise Ratio)

- 1000:1

Repeatability

- ±0.079″ (±2mm)

Response Time

- 0.5 Seconds Fixed (Delay Available)

Model KUSO

Process Connection / Output

- 0 = 1/4″ MNPT / 4-20mA Loop power, NPN & PNP

- 1 = 1/4″ MNPT / 1A SPDT Relay

- 4 = 1/2″ MNPT / 4-20mA Loop power, NPN & PNP

- 5 = 1/2″ MNPT / 1A SPDT Relay

- 6 = 3/4″ MNPT / 4-20mA Loop power, NPN & PNP

- 7 = 3/4″ MNPT / 1A SPDT Relay

Input Power

- 0 = 9-30 VDC Relay, Loop, NPN & PNP

Actuation Point

- 00 = Standard (9/16″ on 1/4″ MNPT / 1-1/4″ on 1/2″ & 3/4″ MNPT)

- XX = Customer Length (1/4″ MNPT up to 36″ / 1/2″ & 3/4″ MNPT up to 96″)

Cable Length

- 0= Standard (12″)

- XX = Custom length in Feet

Temperature Range

- -4°F to 212°F (-20°C to 100°C)

Pressure Range

- 1/4″ MNPT – Vacuum to 100 psig (6.89 bar)

- 1/2″ & 3/4″ MNPT – Vacuum to 500 psig (34.47 bar)

Sensitivity (Signal-to-Noise Ratio)

- 500:1

Repeatability

- ±0.079″ (±2mm)

Response Time

- 0.5 Seconds Fixed (Delay Available)