Accu-Rate Pump Setting Gauge®

Application

The KENCO Accu-Rate Pump Setting Gauges® utilize precision scientific glass to provide the most accurate reading possible for calibrating the flow rate of a chemical metering pump. They are also used to periodically monitor the performance and accuracy of a chemical injection system. Additionally, the Accu-Rate Pump Setting Gauge® can be used as the primary containment reservoir of a fluid that will be pumped into a chemical injection system.

The One Minute Test

To check the flow rate of a chemical pump, isolate the chemical in the storage tank from the Accu-Rate Pump Setting Gauge®. The decal on the gauge glass has (2) individual rate scales. The scale on the left side is a volume scale in milliliters. In a one-minute test, the scale will read the pump rate in milliliters per minute. The scale on the right will depend on what type type of flow rate is required; i.e. U.S. Gallons by Volume, Gallons per Hour, Gallons per Day, Liters per Day or Liters per Hour. Keep the isolating valve closed and observe the number of marks the liquid level passes in one minute. This will give you the actual chemical pump flow rate. If the rate is not the one desired, make an adjustment to the chemical pump flow rate and conduct as many one-minute tests as is necessary to set the chemical pump rate to the rate desired.

Gauge Features

- Precision borosilicate glass sight tube delivers precise rate calibration from 0.05% to 0.2%

- Accu-Rate Pump Setting Gauge® will calibrate pump flow rates up to 1095 Gallons per Day and 4140 Liters per Day.

- Clear polycarbonate shield for impact resistance is standard on all models.

- Five (5) scale options are available: U.S. Gallons by Volume (USG), Gallons per Hour (GPH), Gallons per Day (GPD), Liters per Hour (LPH) and Liters per Day (LPD) – Standard volumetric scale in ML on all units.

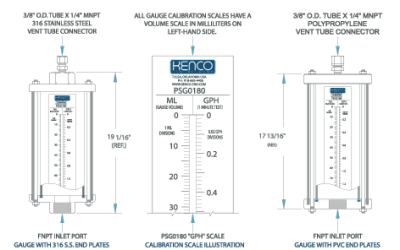

- Tubing connector assembly on top of unit is standard on units with 316 S.S. and PVC End Plates.

- Standard end plate materials are 316 S.S., PVC, CPVC, Hastelloy C-276 and Alloy 20. Other materials available upon request.

- Drain holes in lower end plate eliminate condensation build-up.

- Redline tape can be applied to the sight tube for better visibility of clear liquids. The Redline tape will magnify visibility in the portion of the glass sight tube that contains liquid.

Gallery

Specifications

Specifications

| GAUGE MODEL NUMBER |

END PLATE MATERIAL |

GAUGE VOLUME |

MAXIMUM PUMPING RATE (BASED ON A 1 MINUTE TEST) |

INLET PORT SIZE |

ENG PLATE O.D. |

||||

| ML | USG | GPH | GPD | LPH | LPD | ||||

| PSG0100 | S | 100 | 0.0264 | 1.58 | 38 | 6 | 144 | 1/2″ | 2-7/8″ |

| P/CP/HC/A20 | 3″ | ||||||||

| PSG0180 | S | 180 | 0.0476 | 2.84 | 68.5 | 10.8 | 258 | 1/2″ | 2-7/8″ |

| P/CP/HC/A20 | 3″ | ||||||||

| PSG0404 | S | 404 | 0.107 | 6.4 | 154 | 24.3 | 580 | 3/4″ | 3-3/8″ |

| P/CP/HC/A20 | 3-1/2″ | ||||||||

| PSG0720 | S | 720 | 0.19 | 11.4 | 274 | 43.2 | 1035 | 1″ | 3-7/8″ |

| P/CP/HC/A20 | 4″ | ||||||||

| PSG1620 | S | 1620 | 0.428 | 25.6 | 615 | 97 | 2330 | 1″ | 4-7/8″ |

| P/CP/HC/A20 | 5″ | ||||||||

| PSG2880 | S | 2880 | 0.76 | 45.6 | 1095 | 172 | 4140 | 1″ | 5-7/8″ |

| P/CP/HC/A20 | 6″ | ||||||||

Specifications

End Plate Material

- S = 316 Stainless Steel

- P = PVC

- CP = CPVC

- HC = Hastelloy C-276

- A20 = Alloy 20

* Other end plate materials available. Consult factory for options

Gasket Material

- A = Aflas

- B = Buna-N

- E = Ethylene Propylene

- V = Fluorocarbon

- T = PTFE Envelope with Neoprene Filler

* Other gasket materials available. Consult factory for options.

Scale Calibration Options

- USG = U.S. Gallons by Volume

- GPH = Gallons Per Hour

- GPD = Gallons Per Day

- LPH = Liters Per Hour

- LPD = Liters Per Day

* NOTE: Scale type based on a one minute test.

Tubing Connector Material

- S Models = 316 Stainless Steel

- P Models = Polypropylene

* Gauges constructed with end plate material options CP, HC and A20 supplied without tubing connector fitting.