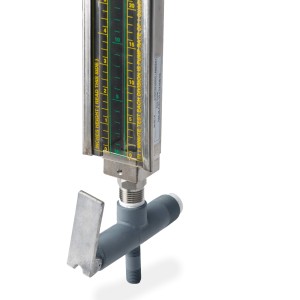

7000 Series Injection Rate Gauge

Applications

The 7000 Injection Rate Gauge is of the same construction as the 5700 Gauge but is provided with a spring-loaded test valve similar to the valve supplied on the 779 Drum Gauge. The test valve is used to isolate the chemical supply tank from the gauge to conduct a one minute calibration test for the chemical pump.

The test valve has a 1/2″ coupler welded to the side for mounting the 7000 Gauge to the valve. The valve mounts in the 3/4″ outlet of a 55 gallon horizontal drum. The bottom connection for the chemical pump suction line is 1/4″ NPT. The test valve is available in either zinc plated carbon steel or 302/304 stainless steel.

* NOTE: Kenco can provide custom scales to meet the calibration requirements of the 7000 level gauge. The Polycarbonate custom scales are usually engraved and paint-filled. If you are needing scales indicating tank volume or other scale calibrations, please consult the factory.

Gallery

Specifications

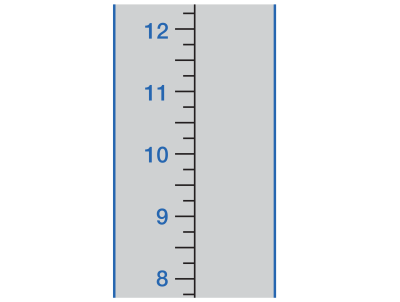

Custom Shields

KENCO can provide custom scales to meet your needs. The Polycarbonate custom scales are usually engraved and paint-filled. If you are needing scales indicating tank volume or other scale calibrations, please consult the factory.

** IMPORTANT: Pressure and temperature are dependent on the length of glass and the elastomer chosen. Please consult the factory for minimum and maximum pressure and temperature constraints.

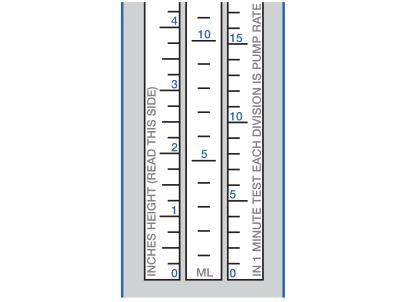

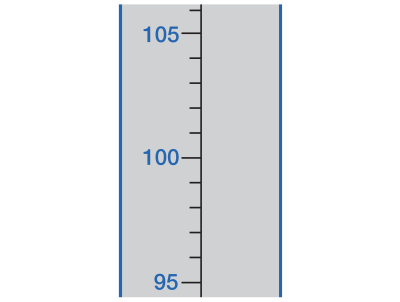

Shield Options - RH

The Rate/Height shield is used for checking the pump rate of a chemical pump. It is calibrated in QTS/24 hrs., ML/Min and has a height scale labeled in 1/4″ increments.

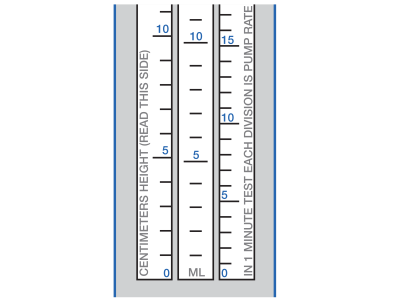

Shield Options - MRH

The Metric Rate/Height shield is calibrated in ML/Min and Liters/24 hrs. The height scale is labeled in 1 CM divisions.

Shield Options - L

The Clear Polycarbonate shield has no markings, and provides 100% visibility as well as environmental protection.

Process Connections

Gauge

- 1/2″ MNPT

Test Valve

- Tank Connection – 3/4″ MNPT

- Pump Connection – 1/4″ MNPT

Housing Material

- C = Zinc Plated Carbon Steel

- A = All Wetted Parts 316 Stainless Steel with 304 Stainless Steel Frame

- W = All Wetted Parts 316 Stainless Steel with Zinc Plated Carbon Steel Frame

Sight Tube Material

- 5/8″ O.D. Standard Glass

*Other sight tube materials available. Consult factory for options.

Seals

- V = Fluorocarbon

- A = Aflas

- B = Buna-N

- E = Ethylene Propylene

- T = PTFE

*Other seal materials available. Consult factory for options.